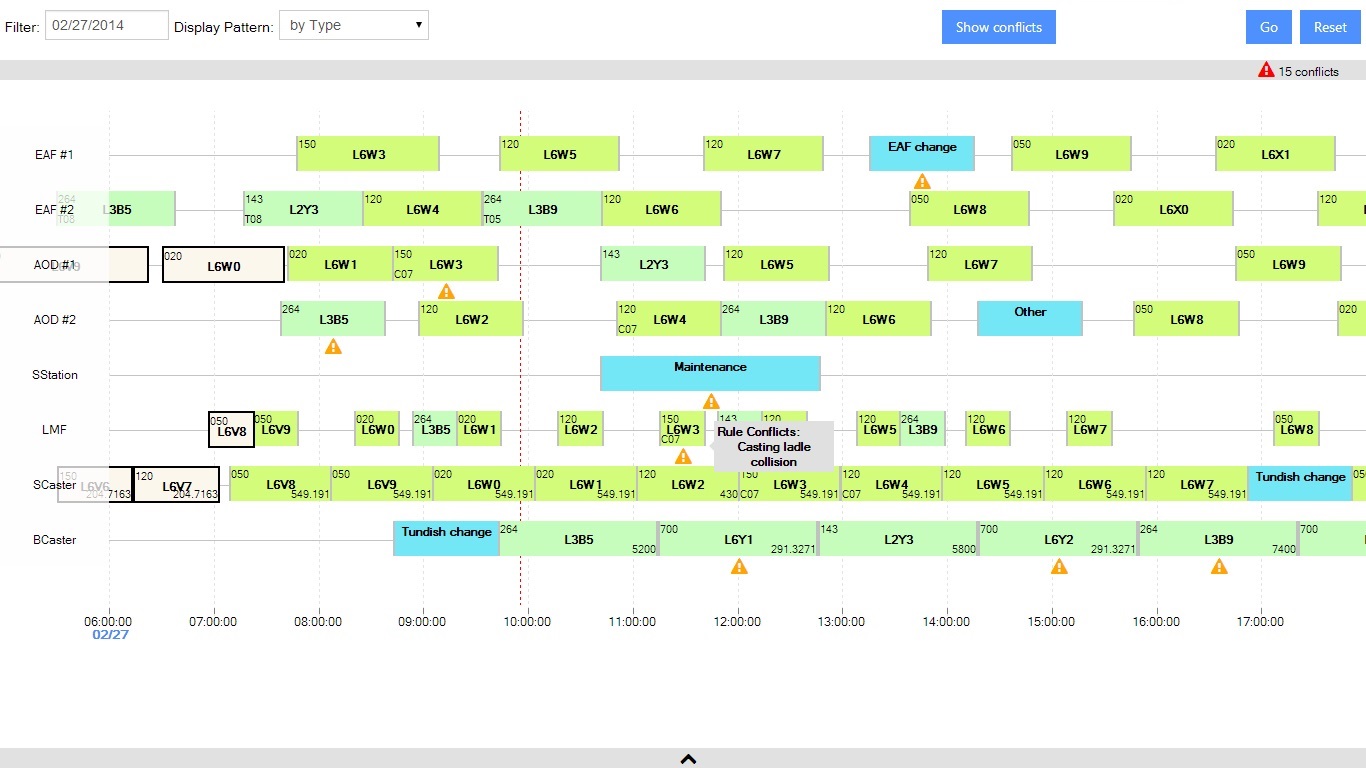

Melt Shop Production On Track

Schedule melt orders and analyze possible outcomes based on predetermined production rules

This application queries the ERP for the melt orders and then allows the Melt Shop Scheduler to reorder the caster lineup and see how the whole melt shop accommodates the heats, tundish changes and other events according to predetermined rules.

FEATURES

- Template optimization algorithm to pre-populate the lineup

- Heat route pre-determined by steel grade

- Rich set of rules that includes process times, transport, ladle usage and alternative routes

- Rules are parametrized by product type and grade families

- Gantt Type visualization, drag and drop operation

- Synchronization with actual events in real time

- Perfect starting point for a more comprehensive optimization

TECHNOLOGIES

- HTML5/AJAX Web Application

- MS SQL Server database